Topics

We organise our actions in six thematic & strategic agendas:

Strategic Agendas:

Bio-economy

Circular Construction

Chemicals/Plastics

Manufacturing Industry

Food Chain

Water Cycles

Seven leverages provide additional support:

Leverage effects:

Lever Policy Instruments

Lever Circular Procurement

Lever Communication

Lever Innovation & Entrepreneurship

Lever Financing

Lever Jobs & Skills

Lever Research

What, why and how?

Why are we pursuing a circular economy?

Future visions 2050

How do we see our circular future?

About our management

Who steers what at Flanders Circular?

Our Approach / Strategic Agendas

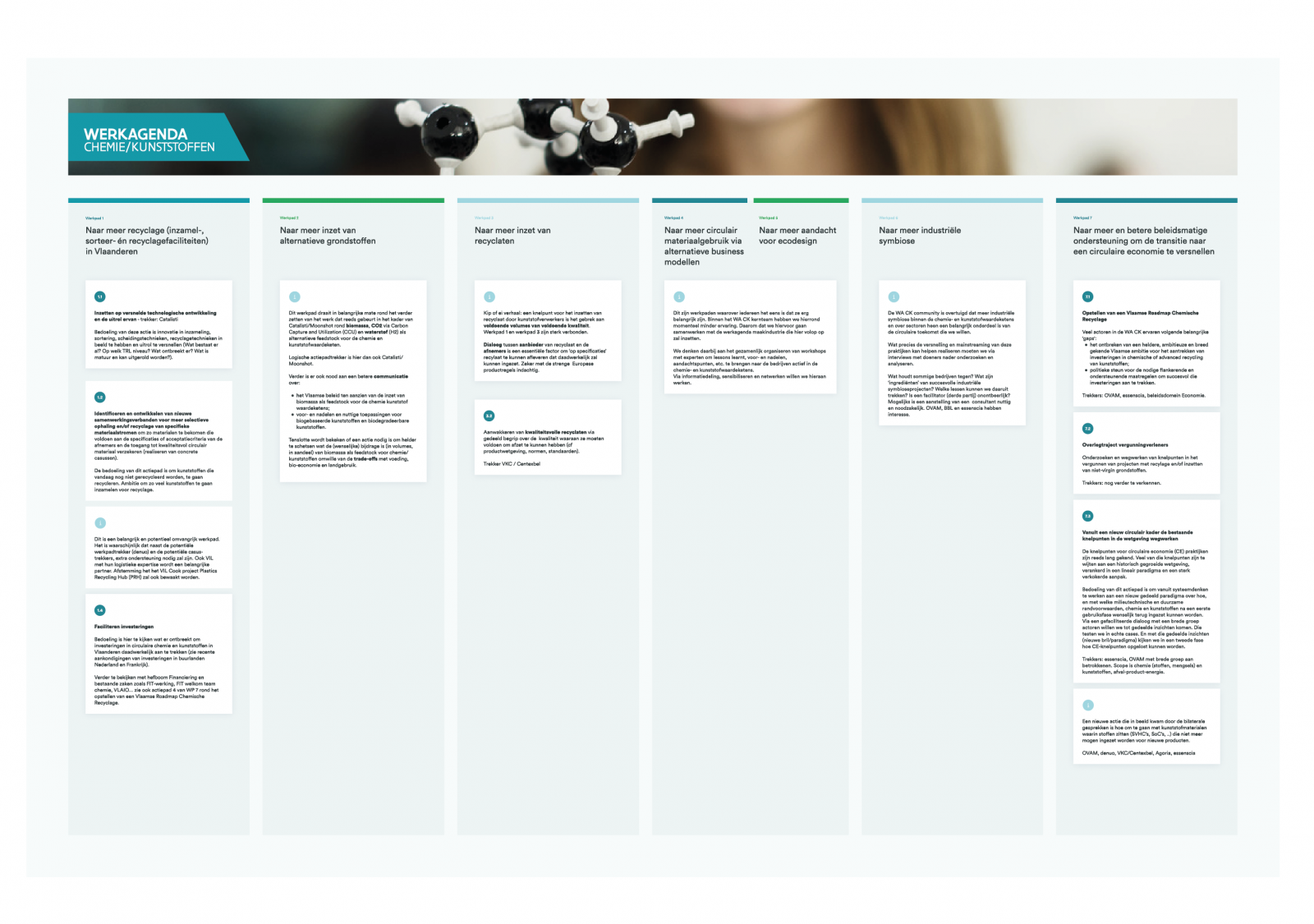

Chemicals/Plastics

Work paths and actions

The signatories of the strategic agenda are implementing concrete actions and projects within the working paths and associated action paths below:

Work path 1. We work together towards more recycling (collection, sorting and recycling facilities) in Flanders through:

- Commitment to accelerated technology development and roll-out

- Identify and develop new partnerships for more selective collection and/or recycling of specific material streams

- Insight into material stocks and flows

- The facilitation of investment

Work path 2. We are working together towards more use of alternative raw materials through:

- Investigating potential and drawing up a strategy for deployment of bio-based raw materials (in chemicals and plastics)

- Investigating or implementing incentives for biomass and CO2 feedstock deployment

- Clarity on definition and framework conditions for deployment of bio-based and biodegradable plastics

- Insights on levers for scaling up industrial-scale CCU applications

Work Path 3. We are working together towards more use of recyclates through:

- Encouraging the deployment of recyclates through coherent and mutually reinforcing incentives

- Fuelling quality recyclates through a shared understanding about quality

- Investigating level playing fields for products entering the market

- Raising awareness to increase support for recycled plastics

Work path 4. We work together towards more circular use of materials through alternative business models via:

- Informing stakeholders

- Learning from existing experience

- Setting up case studies to capture learning experiences

- Investigate how to promote alternative business models

Work path 5. We are working together towards more focus on ecodesign through:

- Tracking developments towards the move to systems thinking

- Realisations within concrete cases

- Identifying and implementing incentives to encourage eco-design

Work path 6. We are working together towards more industrial symbiosis through:

- Facilitating concrete realisations around industrial symbiosis

- Flattening the support framework for industrial symbiosis

Work path 7. We are working together towards more and better policy support to:

- Clarify the policy vision around circular economy

- Set up a consultation process with licensing authorities

- Remove existing legislative bottlenecks

- Increase the social impact of support programmes

1.1

Commit to accelerated technology development and rollout - Accelerator: Catalisti

The aim of this action is to have a picture of innovation in collection, sorting, separation techniques, recycling techniques and to accelerate roll-out (What already exists? At which TRL level? What is missing? What is mature and can be rolled out).

Commit to accelerated technology development and rollout - Accelerator: Catalisti

The aim of this action is to have a picture of innovation in collection, sorting, separation techniques, recycling techniques and to accelerate roll-out (What already exists? At which TRL level? What is missing? What is mature and can be rolled out).

1.2

Identify and develop new partnerships for more selective collection and/or recycling of specific material streams in order to obtain materials that meet customers' specifications or acceptance criteria and ensure access to quality circular materials (realisation of concrete cases).

The aim of this action pathway is to start recycling plastics that are not being recycled today. Ambition to start collecting so many plastics for recycling.

Identify and develop new partnerships for more selective collection and/or recycling of specific material streams in order to obtain materials that meet customers' specifications or acceptance criteria and ensure access to quality circular materials (realisation of concrete cases).

The aim of this action pathway is to start recycling plastics that are not being recycled today. Ambition to start collecting so many plastics for recycling.

i

This is an important and potentially extensive work path. It is likely that in addition to the potential work path puller (denuo) and the potential case pullers, additional support will be needed. VIL with their logistics expertise will also be an important partner. Alignment it the VIL Cook project Plastics Recycling Hub (PRH) will also be monitored.

This is an important and potentially extensive work path. It is likely that in addition to the potential work path puller (denuo) and the potential case pullers, additional support will be needed. VIL with their logistics expertise will also be an important partner. Alignment it the VIL Cook project Plastics Recycling Hub (PRH) will also be monitored.

1.4

Facilitating investments

The aim here is to see what is missing to actually attract investment in circular chemistry and plastics in Flanders (see recent announcements of investments in neighbouring Netherlands and France).

To be considered further with leverage Funding and existing issues such as FIT operation, FIT welcome team chemistry, VLAIO.... see also action path 4 of WP 7 around the drafting of a Flemish Roadmap Chemical Recycling.

Facilitating investments

The aim here is to see what is missing to actually attract investment in circular chemistry and plastics in Flanders (see recent announcements of investments in neighbouring Netherlands and France).

To be considered further with leverage Funding and existing issues such as FIT operation, FIT welcome team chemistry, VLAIO.... see also action path 4 of WP 7 around the drafting of a Flemish Roadmap Chemical Recycling.

i

This work path largely revolves around continuing the work that is already happening in the context of Catalisti/Moonshot around biomass, CO2 via Carbon Capture and Utilization (CCU) and hydrogen (H2) as an alternative feedstock for the chemical and plastic value chain.

Logical action pathfinder is therefore Catalisti/Moonshot.

Furthermore, there is also a need for better communication about:

This work path largely revolves around continuing the work that is already happening in the context of Catalisti/Moonshot around biomass, CO2 via Carbon Capture and Utilization (CCU) and hydrogen (H2) as an alternative feedstock for the chemical and plastic value chain.

Logical action pathfinder is therefore Catalisti/Moonshot.

Furthermore, there is also a need for better communication about:

- Flemish policy on the use of biomass as a feedstock for chemical plastic value chains;

- Pros and cons and useful applications for bio-based plastics and biodegradable plastics.

i

Chicken or egg story: a bottleneck for the deployment of recyclate by plastic converters is the lack of sufficient volumes of sufficient qualitystrong>. Work path 1 and work path 3 are strongly linked.

Dialogue between supplier of recyclate and the customers is an essential factor to deliver 'on-specification' recyclate that will actually be able to be used. Especially with strict European product regulations in mind.

Chicken or egg story: a bottleneck for the deployment of recyclate by plastic converters is the lack of sufficient volumes of sufficient qualitystrong>. Work path 1 and work path 3 are strongly linked.

Dialogue between supplier of recyclate and the customers is an essential factor to deliver 'on-specification' recyclate that will actually be able to be used. Especially with strict European product regulations in mind.

3.2

Inciting high-quality recyclatesstrong> through shared understanding about the quality they must meet to have sales (cf product legislation, norms, standards).

Puller VKC / Centexbel

Inciting high-quality recyclatesstrong> through shared understanding about the quality they must meet to have sales (cf product legislation, norms, standards).

Puller VKC / Centexbel

i

Workpaths 4 and 5 are workpaths that everyone agrees are very important. Within the WA CK core team, we currently have less experience around this. That is why we will collaborate on this with the manufacturing industry strategic agenda, which will be fully committed to this.

We are thinking of jointly organising workshops with experts to bring lessons learned, advantages and disadvantages, points of interest, etc. to the companies active in the chemical and plastic value chains. Through information sharing, awareness-raising and networking, we want to work on this.

Workpaths 4 and 5 are workpaths that everyone agrees are very important. Within the WA CK core team, we currently have less experience around this. That is why we will collaborate on this with the manufacturing industry strategic agenda, which will be fully committed to this.

We are thinking of jointly organising workshops with experts to bring lessons learned, advantages and disadvantages, points of interest, etc. to the companies active in the chemical and plastic value chains. Through information sharing, awareness-raising and networking, we want to work on this.

i

Workpaths 4 and 5 are workpaths that everyone agrees are very important. Within the WA CK core team, we currently have less experience around this. That is why we will collaborate on this with the manufacturing industry strategic agenda, which will be fully committed to this.

We are thinking of jointly organising workshops with experts to bring lessons learned, advantages and disadvantages, points of interest, etc. to the companies active in the chemical and plastic value chains. Through information sharing, awareness-raising and networking, we want to work on this.

Workpaths 4 and 5 are workpaths that everyone agrees are very important. Within the WA CK core team, we currently have less experience around this. That is why we will collaborate on this with the manufacturing industry strategic agenda, which will be fully committed to this.

We are thinking of jointly organising workshops with experts to bring lessons learned, advantages and disadvantages, points of interest, etc. to the companies active in the chemical and plastic value chains. Through information sharing, awareness-raising and networking, we want to work on this.

i

The WA CK community is convinced that more industrial symbiosis within chemical and plastics value chains and across sectors is an important part of the circular future we want.

What exactly can help accelerate and mainstream these practices we need to explore and analyse further through interviews with doers.

What holds some companies back? What are 'ingredients' of successful industrial symbiosis projects? What lessons can we learn from them? Is a facilitator (third party) indispensable? Possibly an appointment of a consultant is useful and necessary. OVAM, BBL and essenscia are interested.

The WA CK community is convinced that more industrial symbiosis within chemical and plastics value chains and across sectors is an important part of the circular future we want.

What exactly can help accelerate and mainstream these practices we need to explore and analyse further through interviews with doers.

What holds some companies back? What are 'ingredients' of successful industrial symbiosis projects? What lessons can we learn from them? Is a facilitator (third party) indispensable? Possibly an appointment of a consultant is useful and necessary. OVAM, BBL and essenscia are interested.

7.1

Preparation of a Flemish Roadmap on Chemical Recycling

Many actors in the WA CK experience the following key 'gaps':

Preparation of a Flemish Roadmap on Chemical Recycling

Many actors in the WA CK experience the following key 'gaps':

- the lack of a clear, ambitious and widely known Flemish ambition for attracting investment in chemical or advanced recycling of plastics;

- political support for the necessary flanking and support measures to successfully attract that investment.

7.2

Consultation process licensing authorities

Investigate and remove bottlenecks in licensing projects involving recycling and/or deployment of non-virgin raw materials.

Pullers: to be explored further.

The aim of this action pathway is to start recycling plastics that are not being recycled today. Ambition to start collecting so many plastics for recycling.

Consultation process licensing authorities

Investigate and remove bottlenecks in licensing projects involving recycling and/or deployment of non-virgin raw materials.

Pullers: to be explored further.

The aim of this action pathway is to start recycling plastics that are not being recycled today. Ambition to start collecting so many plastics for recycling.

7.3

From a new circular framework, remove existing legislative bottlenecks

The bottlenecks to circular economy (CE) practices have long been known. Many of these bottlenecks can be attributed to historically based legislation, anchored in a linear paradigm and a highly compartmentalised approach.

The aim of this action path is to work on a new shared paradigm based on systems thinking about how, and with what environmental and sustainable preconditions, chemicals and plastics can desirably be reused after an initial use phase. Through a facilitated dialogue with a broad group of actors, we want to arrive at shared insights. We test these in real cases. And using these shared insights (new perspective/paradigm), in a second phase we look at how CE bottlenecks can be solved.

Drivers: essenscia, OVAM with broad group of stakeholders. Scope is chemicals (substances, mixtures) and plastics, waste-product-energy.

From a new circular framework, remove existing legislative bottlenecks

The bottlenecks to circular economy (CE) practices have long been known. Many of these bottlenecks can be attributed to historically based legislation, anchored in a linear paradigm and a highly compartmentalised approach.

The aim of this action path is to work on a new shared paradigm based on systems thinking about how, and with what environmental and sustainable preconditions, chemicals and plastics can desirably be reused after an initial use phase. Through a facilitated dialogue with a broad group of actors, we want to arrive at shared insights. We test these in real cases. And using these shared insights (new perspective/paradigm), in a second phase we look at how CE bottlenecks can be solved.

Drivers: essenscia, OVAM with broad group of stakeholders. Scope is chemicals (substances, mixtures) and plastics, waste-product-energy.

i

A new action that came into view through the bilateral talks is how to deal with plastic materials containing substances (SVHCs, SoCs, etc.) that should no longer be used for new products.

OVAM, denuo, VKC/Centexbel, Agoria, essenscia

A new action that came into view through the bilateral talks is how to deal with plastic materials containing substances (SVHCs, SoCs, etc.) that should no longer be used for new products.

OVAM, denuo, VKC/Centexbel, Agoria, essenscia