Topics

We organise our actions in six thematic & strategic agendas:

Strategic Agendas:

Bio-economy

Circular Construction

Chemicals/Plastics

Manufacturing Industry

Food Chain

Water Cycles

Seven leverages provide additional support:

Leverage effects:

Lever Policy Instruments

Lever Circular Procurement

Lever Communication

Lever Innovation & Entrepreneurship

Lever Financing

Lever Jobs & Skills

Lever Research

What, why and how?

Why are we pursuing a circular economy?

Future visions 2050

How do we see our circular future?

About our management

Who steers what at Flanders Circular?

CIRCLETEX

National circular collection system for textiles

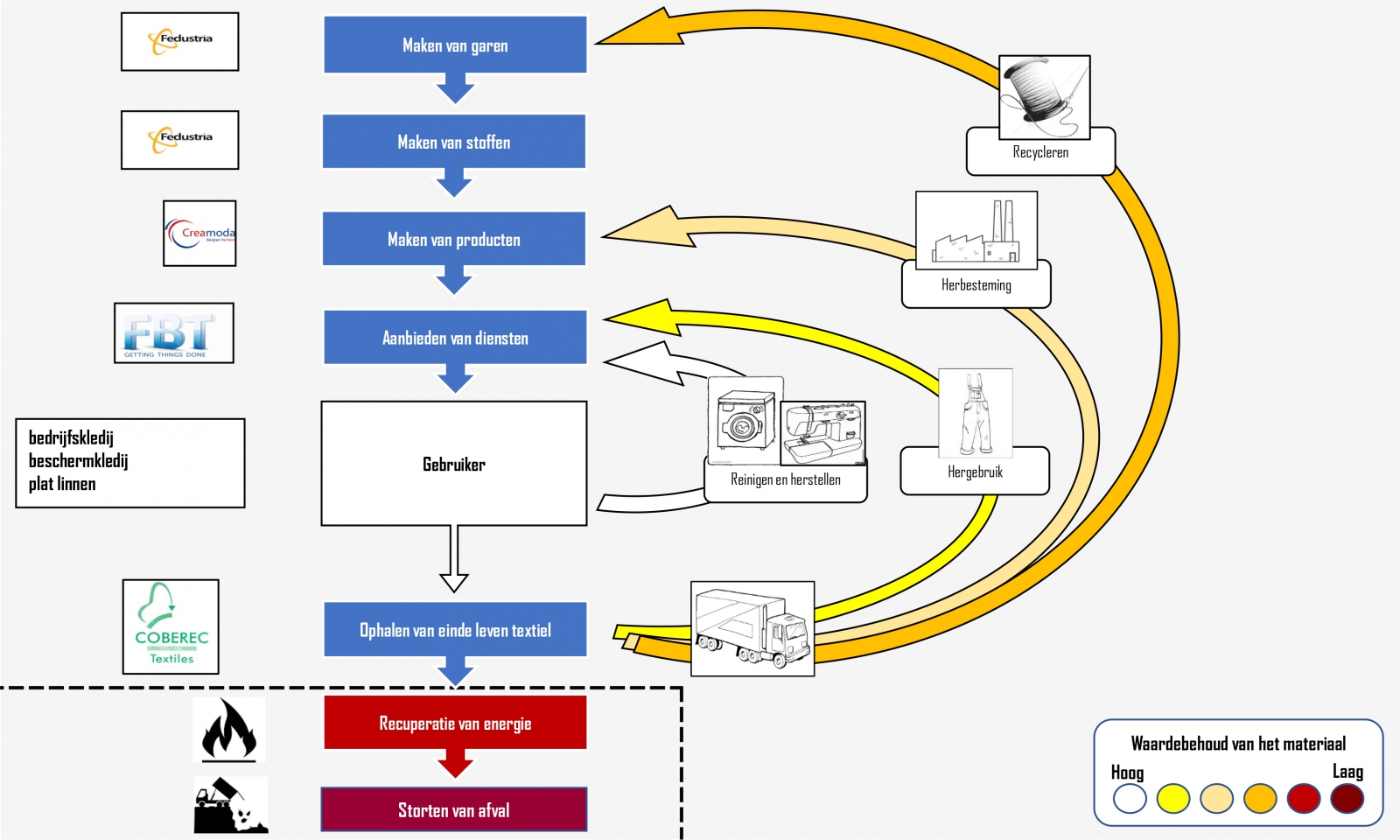

At present, most end-of-life (industrial) textiles still disappear into the incinerator along with residual waste. The rest is disposed outside the EU or recycled to a limited extent in our country and in neighbouring countries. It is both an ecological and economic loss to simply burn these valuable raw materials or let them leave Europe. It is also difficult to control what happens to these materials outside the EU.

The Belgian fashion federation Creamoda wants to take a proactive approach and set up a national collection system together with the Federation of Belgian Textile Care (FBT), the Federation of Belgian Textile, Wood and Furniture Producers (Fedustria) and the Federation of the Belgian Waste and Recycling Sector (Denuo) to selectively collect the released textile flows in Belgium, sort them for local reuse and recycle them into new fibres if possible.

Concretely, with this project we want to first conduct research on the quantities and composition of the produced and end-of-life textiles in Belgium, as well as on the existing recycling technologies and standards, in order to then look for possible collection and processing scenarios for our collection concept.

The aim is for this project to culminate in the creation of a management organisation for end-of-life textiles, in the form of a non-profit association.

Creamoda vzw

Partners Federatie van de Belgische textielverzorging vzw, Fedustria vzw, Federatie van de Belgische recuperatie van textiel vzw, Recydata vzw

Sectors

Themes

Organisations

Website

MOST IMPORTANT

RESULTS

- We developed a reporting system to map the quantity and composition of workwear coming onto the market in Belgium. We also made an inventory of the quantities of end-of-life textiles.

- We researched the different technologies available and their limitations in order to return textile fibres to the chain in an ecological and economic way.

- We defined a number of collection and processing scenarios to find out where in the chain our collection concept Circletex can add value and how it can fulfil its primary objectives.

- We analysed the existing standards and labels for Recycled Content in fabrics and workwear. We want to develop a protocol to calculate the share of Recycled Content in a uniform way and to certify it with a Circletex certificate.

MOST IMPORTANT

LESSONS LEARNED

- To reinforce the objectives of Circletex, we will have to deploy a series of stimulating actions among various actors in the chain, such as financial incentives, extra communication and pilot projects or working groups.

- We see a great future in chemical recycling, but it is not yet industrially available in the EU because it is so expensive. So far, only Saxcell in Europe manages to recycle polyester in a chemical way, and that capacity is almost entirely taken up by Coca-Cola.

- Clothing with a lot of elastane, many different fibres and hard points is still difficult to recycle. Also, the information on the composition label is not always correct. Garment producers need to cooperate better with the recycling sector so that reuse is already taken into account in the design.

WHAT DOES

THE FUTURE HOLD?

With the Circletex project, we have succeeded in developing the three main activities of the future non-profit Circletex organisation, namely a reporting and monitoring system for end-of-life business textiles, a uniform and reliable certification system for Recycled Content in business textiles and the facilitation of cooperation on circularity within the chain.

The non-profit Circletex is currently officially 'in formation'. We will initially start up the system with our own resources, but a UPV and/or take-back obligation will ensure its long-term existence. Once the collection of the first textile flow is functioning optimally, we want to expand the system step by step to all other textile flows.